Quality Assurance

Factoria Engineering Works has a company quality philosophy to manufacture and supply parts and spares that conform to the customer’s drawings and requirements and ensure complete satisfaction with the delivered parts.

The quality assurance at Factoria Engineering Works applies ISO 9002 standards as part of our complete in-house developed quality system that provides full traceability on all parts we manufacture. ISO 9002 offers quality assurance guidelines for the production, servicing, and installation.

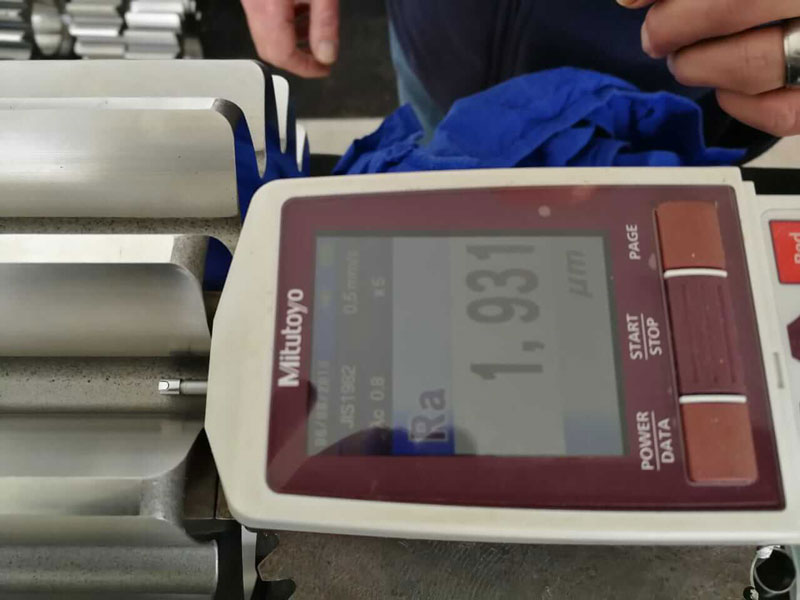

Quality assurance at Factoria Engineering Works for gear testing

As part of the quality assurance at Factoria Engineering Works, we use the following assessments tools, among others:

- Centre testing machines

- Gear tooth profile tester

- Pitch tester

- Hardness testers

Quality assurance at Factoria Engineering Works from suppliers

Through quality assurance at Factoria Engineering Works, we promote the involvement of our suppliers in our operational requirements. In addition, we regard our suppliers as a fundamental part of the supply chain process. By building sound business and operational relationships, we can ensure the efficient turn-around of the materials we order.

Comprehensive quality assurance at Factoria Engineering Works

We guarantee comprehensive quality assurance at Factoria Engineering Works on all the services we offer, including CNC precision machining, gear cutting services, and other machining services. This covers bevel gears, spur gears and pinions, helical gears and pinions, gear grinding, internal gears, sprockets, worm-wheels and worm-shafts, internal and external splines, scraper winches, rock drills, locomotive parts, and industrial gearing, to only name a few.

Contact Factoria Engineering Works for details

Our quality control department checks all the manufacturing completed at our machining centres on completion as part of our promise to quality assurance at Factoria Engineering Works. In addition, random spot checks are executed during the machining of each batch, and our quality assurance inspector carries out a final inspection of the entire batch. For more information about the quality assurance at Factoria Engineering Works, please contact us today for assistance.