Gear Cutting Facilities:

With plenty of pressure placed on machinery in the industrial and mining sects, there is a particularly high demand for easy to source, reliable and robust spare parts for equipment. Gears, being put under some of the most strain, will need to be replaced at some point. That is why we at Factoria Engineering Works provide our clients with gear cutting facilities that can meet this need perfectly.

This allows us to fabricate a wide spectrum of gear types for replacement parts, marked by manufacturing quality and quick turnarounds, to ensure that your facility suffers minimal downtime when parts need to be replaced.

Our gear cutting facilities can fabricate spur gears, helical gears, internal gears, sprockets, splines, keyways and more.

Gear Manufacturing & Cutting Services:

Our gear cutting facilities allow us to produce a wide range of specialist parts for the mining industry, these include the following:

Bevel Gears

Straight Tooth Bevel Gears with a maximum outside diameter of 450 mm, a face with of 80 mm, up to 8 Module

Broaching Facilities

Our broaching facilities are used for the manufacture of our range of Spares that we supply to the Mining Industry.

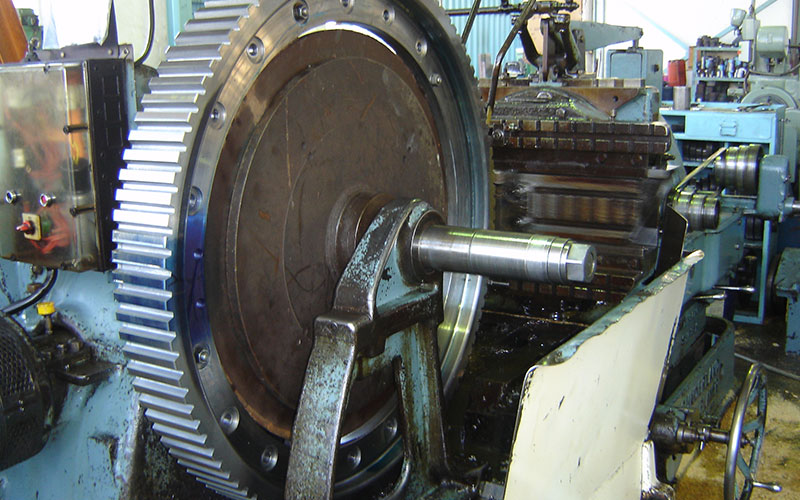

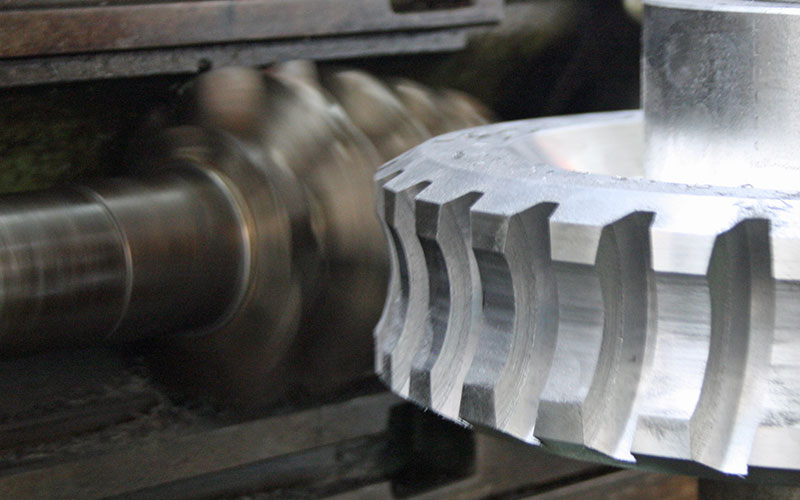

Spur Gears & Pinions

Our gear cutting machines are capable of cutting up to a maximum outside diameter of 1420mm with a maximum face width of 256 mm. Our gear cutting machines consist of a fleet of Gear Planing machines, Gear Hobbers and Fellows Type Gear Shaping machines.

Helical Gears & Pinions

The same gear cutting machines are used for Spur Gears, however due to the Helix Angles the capabilities are reduced. Maximum outside diameter is 1420 mm with a face width of 160 mm.

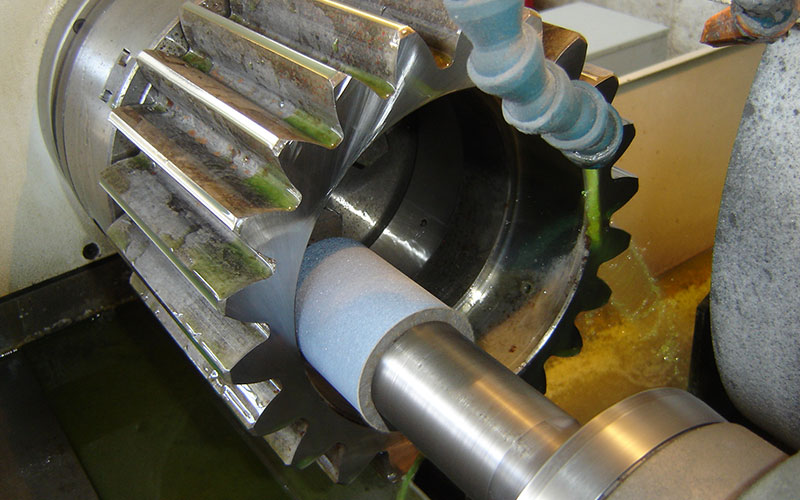

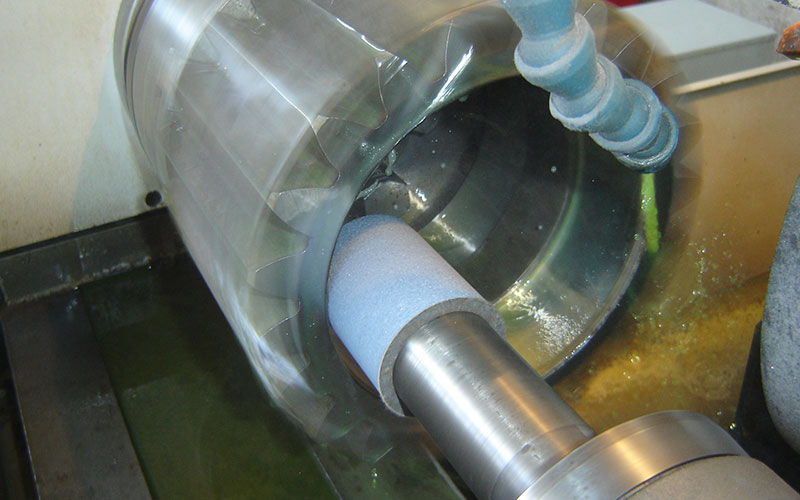

Gear Grinding

With our WMW Niles gear grinding facilities we are able to gear grind helical and spur gears up to 600 mm outside diameter.

Internal Gears

With our Fellows Type gear shaping machines we are capable of cutting Internal Gears up to an outside diameter of 600 mm with a face length of 120 mm

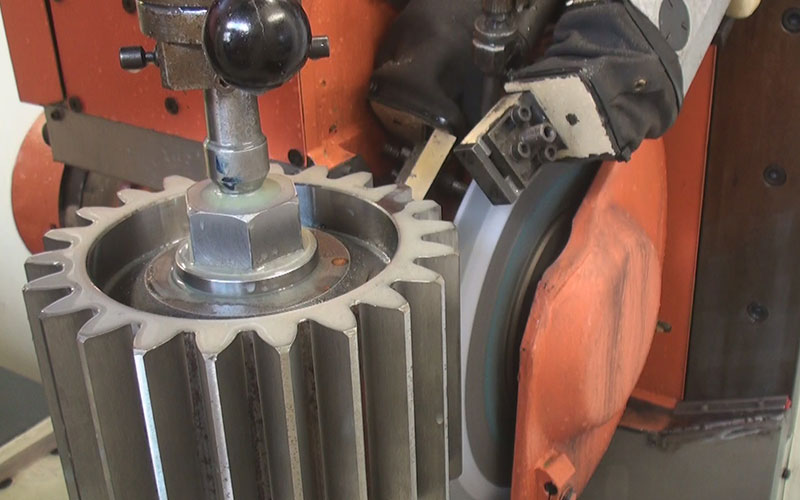

Sprockets

Capable of cutting Sprockets up to 2.5” Pitch.

Worm-wheels and Worm-shafts

Our Hobbing machines allow us to cut worm-wheels up to a 600 mm outside diameter, with the maximum pitch of 50 mm. Matching Worm shafts are manufactured in-house.

Internal Splines and Keyways

Our Slotting machines allow us to cut Internal Splines and Internal Keyways up to a diameter of 600 mm with a maximum length through the bore of 215 mm (change to 400 mm)

External Splines

Our horizontal Hobbing machine allows us to cut Spline shafts up to 1200 mm long.